PP masterbatch production process is divided into grinding pigments, mixed materials (pigments, dispersants, carrier) and extrusion granulation in three steps.

A grinding pigments

Grinding pigments have the following several ways:

1. Polymers Protection Act: The polymer is dissolved in a solvent, and pigment grind together to make about 75% of polymer encapsulated pigment particles to prevent flocculation.

2. fatty acids and salts of the parent pigment system of law: first to make 12 to 16 carbon atoms in the fatty acid metal salt and from 12 to 26 carbon atoms in the fatty acid and the insoluble pigment dispersed into fine particles. The mixture is then granulated pressure knot.

3. Dry milling: Liaohua introduced as Hoechst's patented production methods.

The wet grinding (phase inversion method): as Beijing Yanshan Petrochemical Corporation introduced Ciba Geigy patented production methods. The law is the pigment, polyethylene waxes, acetic acid and water with added gravel grinding mill 20 hours, lapped material from the pump into the tank transfer phase, the phase inversion tank by adding NaOH to adjust the PH to 8 and White spirit added, after heating the high-speed stirring, the pigment phase transfer from water to oil phase to form a size of particles of 0.1 ~ 3mm. Pigment particles are washed with water and dried.

Second, the mix of materials

The material is mixed materials (pigment, dispersant, carrier, antioxidants, ultraviolet absorbers, etc.) was heated in a kneader extruder. Commonly used kneading machine has internal mixer, a drum mixer and the like. The method can also be used pneumatic conveying of solid-phase mixing.

Third, extrusion granulation

Extrusion granulation, often using a screw extruder. With the large number of applications vented twin-screw extruder, these machines are usually included with the vacuum exhaust system and quick changer device to increase the dispersion effect pigments mixed with polypropylene.

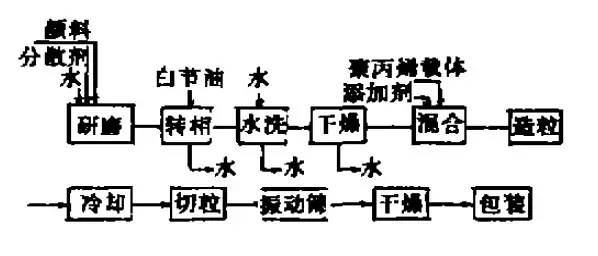

In summary, for in order to carry out wet grinding of pigment particles PP masterbatch production process, the process block diagram shown in Figure 1:

Figure 1 PP masterbatch production flow chart

RAJ Yancheng Masterbatch Co., Ltd. Main polypropylene, nonwovens masterbatch, black masterbatch masterbatch products. If necessary, please call us!

Total Ni Mobile: 13805103263

Hotline: 0515-88322183

- Take a look at the production pr

- The global oil trade is shifting

- Looking back on the journey of h

- Mizlion made a stunning appearan

- Why is it said that polypropylen

- The impact of the Federal Reserv

- Chemical fibers "carry static el

- What are the core considerations

- The High Performance and High Fu